Your Ultimate Guide to Leather

Tillman’s Leather Guide

Not All Leather is the Same.

Because of its durability, versatility, and abundance, leather has been a preferred material for work gloves for hundreds of years. While new materials have been introduced to the market, leather remains the favorite material of welders and tradespeople for its feel, quality and durability.

Tillman® continues to focus on producing high-quality leather welding and work gloves using tried and true manufacturing methods that have been used for over 90 years.

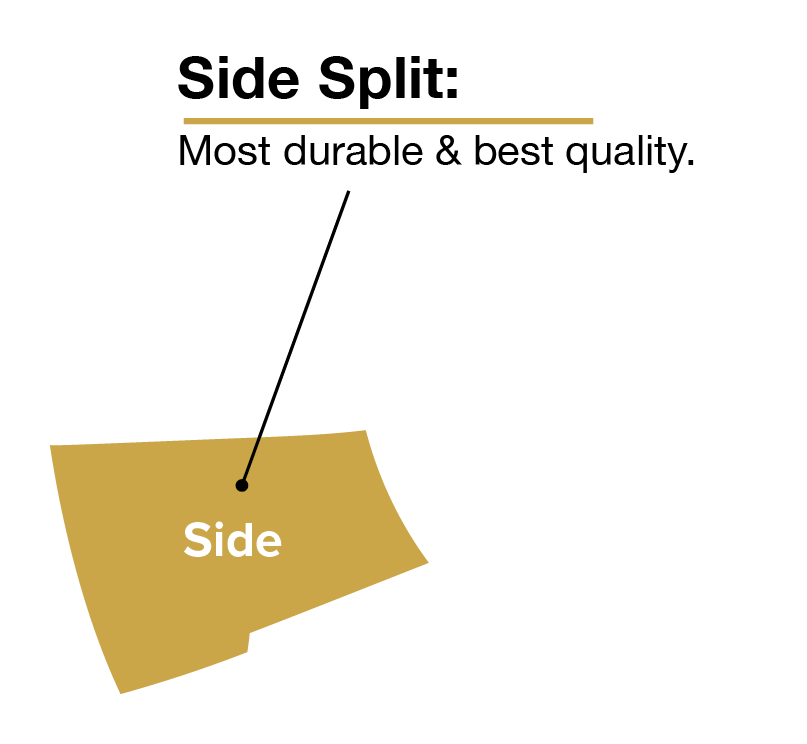

Split Leather

Split Leather gets its name from splitting the hide. Split is the internal layer of the hide and has a fuzzy, napped finish and is commonly known as suede. It is generally associated with larger animals like Cows, Elk or Deer whose hide is thick enough to be split into layers.

Grain Leather

Grain Leather is the top layer of leather. It has a smoother, softer feel than split leather.

Clute Cut

A Clute Cut keeps the palm free of stitching. On the palm side of a clute cut pattern, the palm and all four fingers are cut from one piece of leather. This design offers a great amount of flexibility.

Gunn Cut

The Gunn Cut is the most common pattern found on gloves and features the two middle fingers sewn to the palm. The palm, little finger, and index finger are cut from one piece of leather and the two center fingers are cut from another piece. The design offers great wear and comfort.

Why Choose Leather Gloves?

Elkskin Leather

Cowhide Leather

Deerskin Leather

Pigskin Leather

Goatskin Leather