Complete Protection

Get ANSI/ISEA Standards and

EN Ratings to keep you safe.

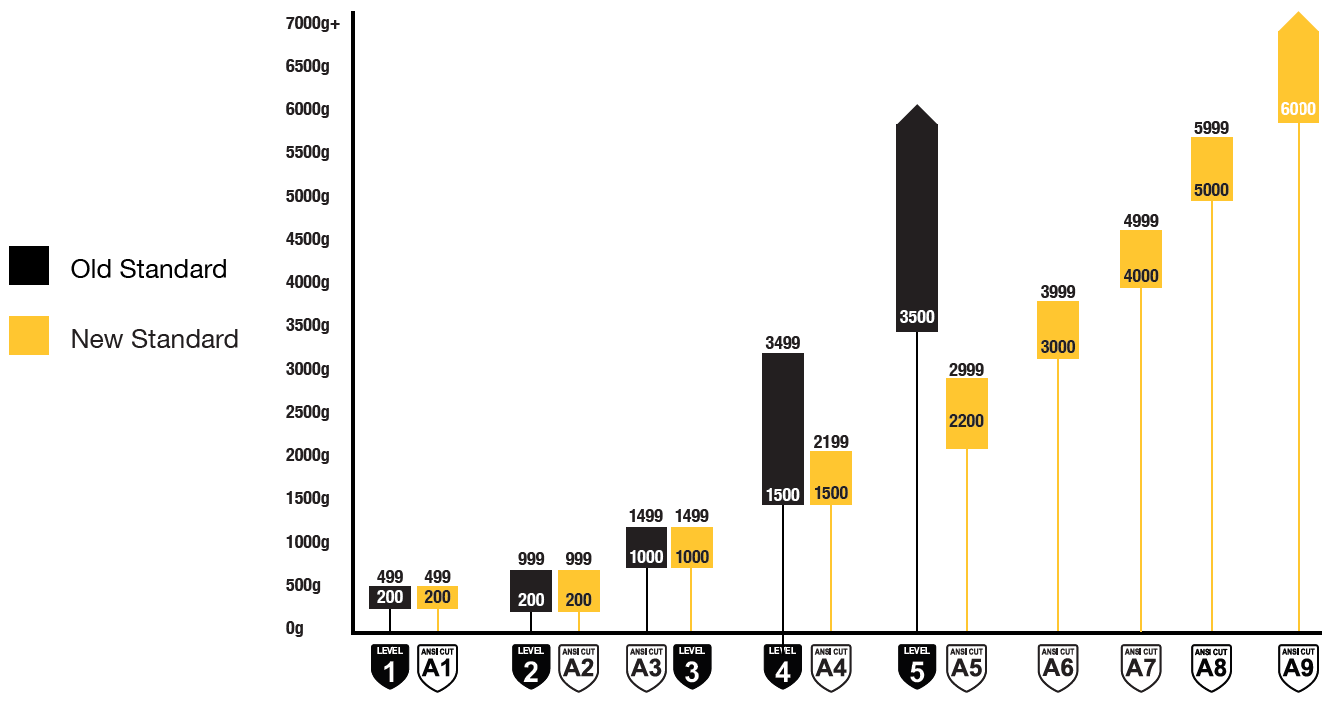

Cut Resistant Levels

Hand accidents do not discriminate.

A hand injury can seriously injure an individual and can also send them off the job for a few days. According to the Bureau of Labor Statistics, in 2018 more than 123,900 workers experienced a hand injury while on the job, accounting for almost eight percent of all nonfatal workplace injuries.

Over the last 15 years, HPPE, high performance polyethylene, or engineered yarns, have seen some of the greatest innovation in producing cut-resistant gloves. HPPE gloves are developed by knitting multiple polyethylene fibers alone, or with other additives like stainless steel or DuPont™ Kevlar® . These threads, when knitted together, create a fiber that delivers a cut resistant material for the user while also providing great dexterity.

What Cut Level Should I Be Using?

Tillman uses both the ANSI 105 and the EN 388 standards for testing. Both standards test gloves for Abrasion, Cut, Tear, and Puncture with both the ANSI and EN standards recognized in the US. With the introduction of ANSI/ISEA 105 (2016) standard in 2016, 105 addressed the classification and testing of hand protection for specific performance properties. With this change, there are now nine cut levels – A1, A2, A3, A4, A5, A6, A7, A8, A9 – Up from 5. These nine cut levels allow users and manufacturers to more accurately determine the level of hand protection they require as it relates to job requirements.

Along with the update in cut resistance, ANSI/ISEA 105 (2016) incorporated a needlestick puncture test as this is a potential risk in the construction and recycling industries.

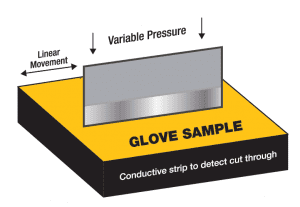

ANSI/ISEA 105 (2016) Cut Standard – How Gloves Are Tested

- A Tomodynameter machine (TDM), which uses a straight blade that cuts in an oscillating, back and forth motion.

- As the blade cuts, more weight is added until the glove material is cut.

- The greater the weight that is required to cut the glove the higher the cut resistance rating.

- The cut distance is 25mm (vs 20mm with the prior standard).

|

WARNING: Leather products can expose you to chemicals including Chromium (hexavalent compounds), which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information, please visit www.p65warnings.CA.gov. |

|

|

DuPont™, Nomex® and Kevlar® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company. |

ANSI/ISEA Levels

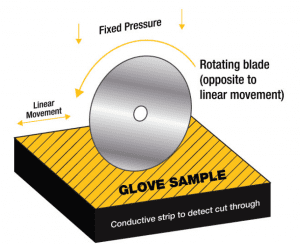

EN 388:P 2016 Cut Standard – How Gloves Are Tested

- A test sample is taken from the palm of a glove.

- A rotating circular blade moves back and forth across the test sample until a cut-through is achieved.

- The test sample is compared to a reference material (usually cloth).

- The reference material and the test sample are cut alternately until at least five results are achieved.

- To help account for a loss in sharpness to the blade, the reference material is cut before and after the test sample.

- The cut resistance is a ratio of the number of cycles needed to cut through the test sample compared to the reference material.

|

EN388 |

RANGE |

CONVERTED |

ANSI/ISEA |

RANGE |

USAGE |

|

2 – 4.9 |

204 – 508 |

|

200 – 499 |

Light cut hazards: Assembly, material handling, packaging, shipping, and receiving. Tillman does not recommend this for cut protection. |

|

5 – 9.9 |

509 – 1,019 |

|

500 – 999 |

Light/medium cut hazards: Assembly, material handling, appliance manufacturing, automotive, construction and maintenance. |

|

10 – 14.9 |

1,019 – 1,529 |

|

1,000 – 1,499 |

Light/medium cut hazards: Small parts assembly with moderately sharp edges, appliance manufacturing, automotive manufacturing, HVAC, construction, forestry, maintenance, packaging, warehousing, and material handling. |

|

15 – 21.9 |

1,530 – 2,242 |

|

1,500 – 2,199 |

Medium cut hazards: Appliance manufacturing, bottle and light glass handling, small parts manufacturing with sharp edges, HVAC, automotive assembly, metal fabrication/stamping, packaging, |

|

22 – 29.9 |

2,243 – 3,058 |

|

2,200 – 2,999 |

Medium/heavy cut hazards: Appliance manufacturing, bottle and light glass handling, HVAC, automotive assembly, metal fabrication/stamping, packaging, aerospace and paper production. |

|

30+ |

3,059+ |

|

3,000 – 3,999 |

High cut hazards: Metal stamping, metal recycling, metal fabrication, HVAC, automotive assembly, glass manufacturing, recycling sorting, aerospace and paper production. |

|

|

|

|

4,000 – 4,999 |

High cut hazards: Metal stamping, metal recycling, metal fabrication, HVAC, automotive assembly, glass manufacturing, recycling sorting, aerospace and paper production. |

|

|

|

|

|

5,000 – 5,999 |

High cut hazards: Assembly of items with sharp edges, metal stamping, metal recycling, metal fabrication, HVAC, automotive assembly, glass manufacturing, recycling sorting, aerospace and paper production. |

|

|

|

|

|

5,000+ |

High cut hazards: Assembly of items with sharp edges, metal stamping, metal recycling, metal fabrication, HVAC, automotive assembly, glass manufacturing, recycling sorting, food processing, aerospace and paper production. |