CERTIFIED FLAME RESISTANT WELDING PROTECTION – Engineered with 9oz Westex® FR-7A® flame resistant cotton that meets rigorous ASTM D6413-10 standards, providing critical self-extinguishing properties when exposed to flame or thermal ignition sources

SUPERIOR WELDING SAFETY WITH SUSTAINED FR PERFORMANCE – This flame resistant welding jacket maintains its protective properties for up to 50 home washings at 145°F or 25 commercial washings up to 165°F, ensuring long-term value and consistent protection

PROFESSIONAL-GRADE COMFORT FOR EXTENDED WELDING SESSIONS – The 100% cotton construction delivers exceptional breathability and flexibility, reducing fatigue during long welding projects while providing the flame resistant protection welders demand

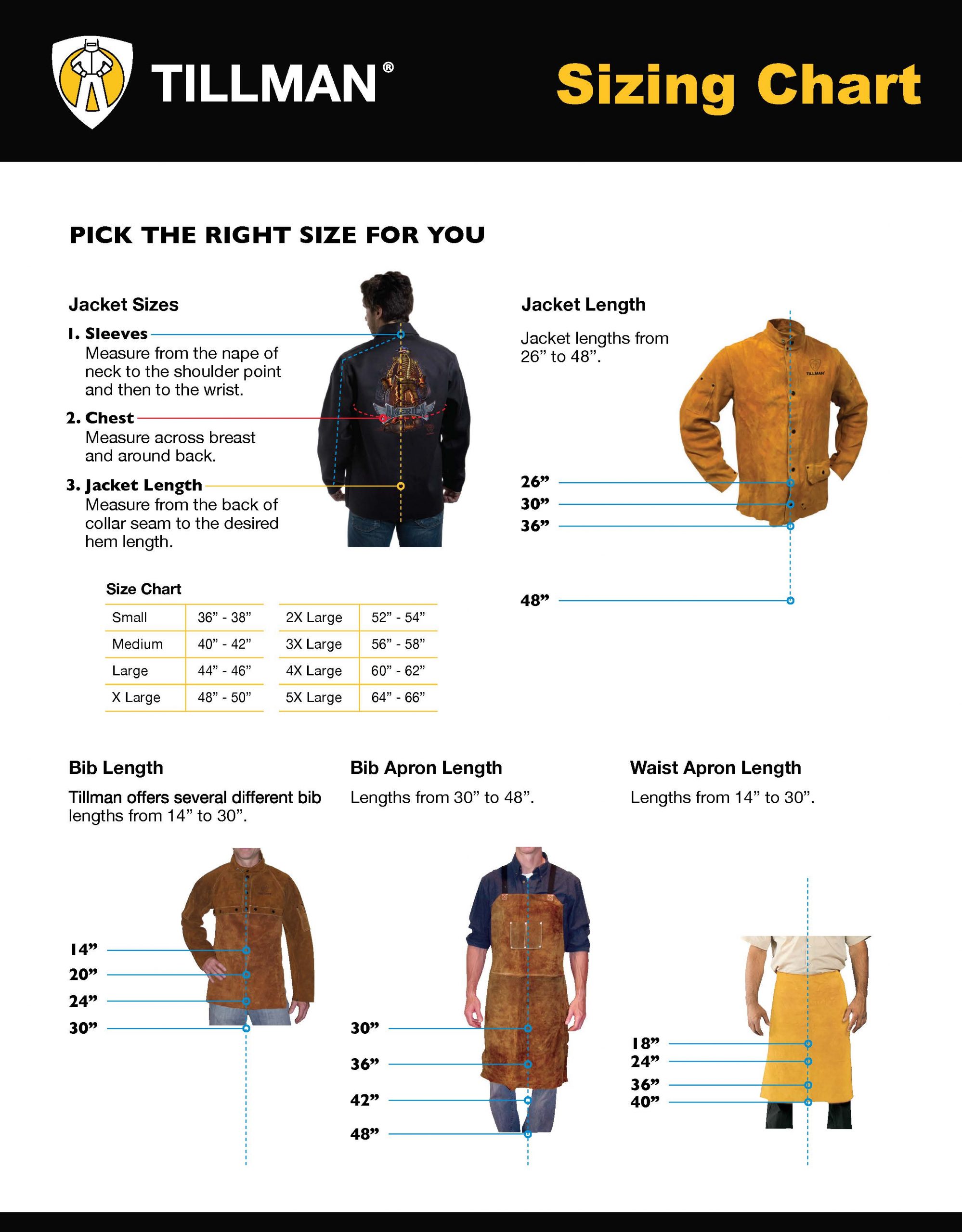

30″ LENGTH WITH RUGGED SNAP CLOSURES – Designed with secure metal snap fasteners for quick donning and doffing with welding gloves, while providing coverage length that protects against sparks and spatter during all welding positions

DUAL INNER POCKET DESIGN FOR WELDING ESSENTIALS – Two convenient interior pockets keep essential tools and personal items secure and protected from workshop hazards while maintaining the jacket’s clean exterior profile

FLAME RESISTANT PROTECTION THAT MEETS INDUSTRY STANDARDS – ASTM D6413-10 certification ensures this flame resistant welding jacket meets the maximum char length requirement of 6 inches as specified in ASTM F1506, providing verified safety performance

AMERICAN-MADE WESTEX® FR-7A® TECHNOLOGY – Constructed with premium US-manufactured flame resistant cotton fabric that delivers consistent protection, comfort, and durability for professional welding environments

DESIGNED FOR PRACTICAL LAYERING IN WELDING ENVIRONMENTS – Sized to comfortably fit over work shirts while maintaining mobility, this flame resistant welding jacket offers versatile protection in varying workshop conditions

| SM – 6230S |

2X – 62302X |

6X – 62306X |

| MD – 6230M |

3X – 62303X |

|

| LG – 6230L |

4X – 62304X |

|

| XL – 6230XL |

5X – 62305X |

|

- 9oz FR cotton construction

- ASTM D6413-10 certified protection

- Self-extinguishing flame properties

- 30″ protective length design

- Metal snap closure system

- Dual interior pocket storage

- US-made Westex FR-7A

- Comfortable washable protection

- 50-wash FR durability

- US Steel green professional appearance

- Proper over-shirt sizing

- Lightweight welding protection

Industries

- Metal Fabrication Workshops

- Industrial Welding Operations

- Construction Welding

- Shipbuilding and Marine Repair

- Automotive Manufacturing

- Pipeline Construction

- Railroad Maintenance

- Aircraft Maintenance & Repair

- Technical Schools and Training Facilities

- Refineries and Chemical Plants

- Power Generation Facilities

- Agricultural Equipment Repair

- Mining Equipment Maintenance

- Defense Manufacturing

- Custom Motorcycle Fabrication

- Metal Art Studios

- Sheet Metal Fabrication

- HVAC Installation and Repair

- Structural Steel Erection

- Equipment Repair Services

Applications

- MIG Welding Operations

- TIG Welding Environments

- Light Cutting Operations

- Grinding and Metal Finishing

- Torch Cutting Procedures

- Field Welding Projects

- Production Line Welding

- Spot Welding Operations

- Heat Treatment Processes

- Maintenance Welding Tasks

- Overhead Welding Positions

- Vertical Welding Applications

- Flat Position Welding

- Tack Welding Procedures

- Light Fabrication Work

- Workshop Assembly Tasks

- Technical Training Environments

- Metal Finishing Operations

- Spark-Producing Activities

- Flame Cutting Applications

- Welding Inspection Work

- Metal Preparation Tasks

- Metalworking Education

- Repair Welding Projects