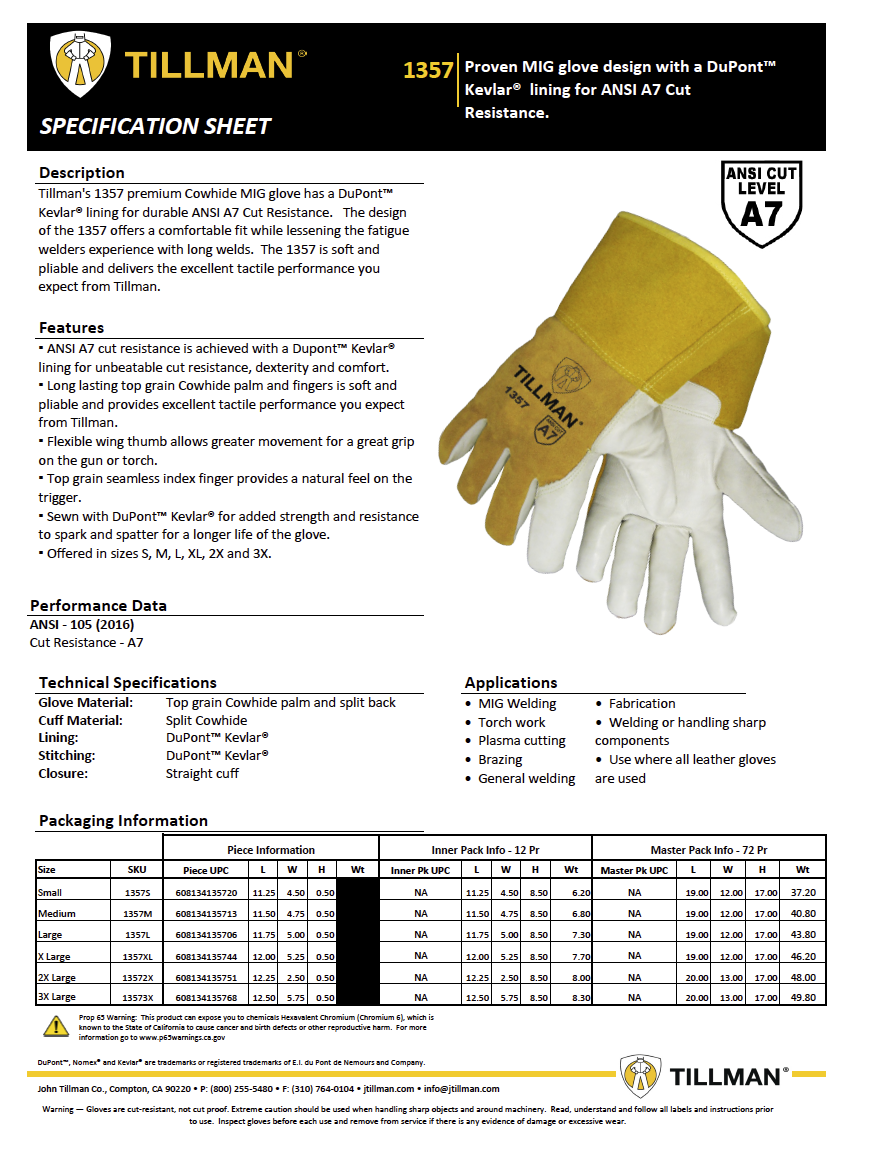

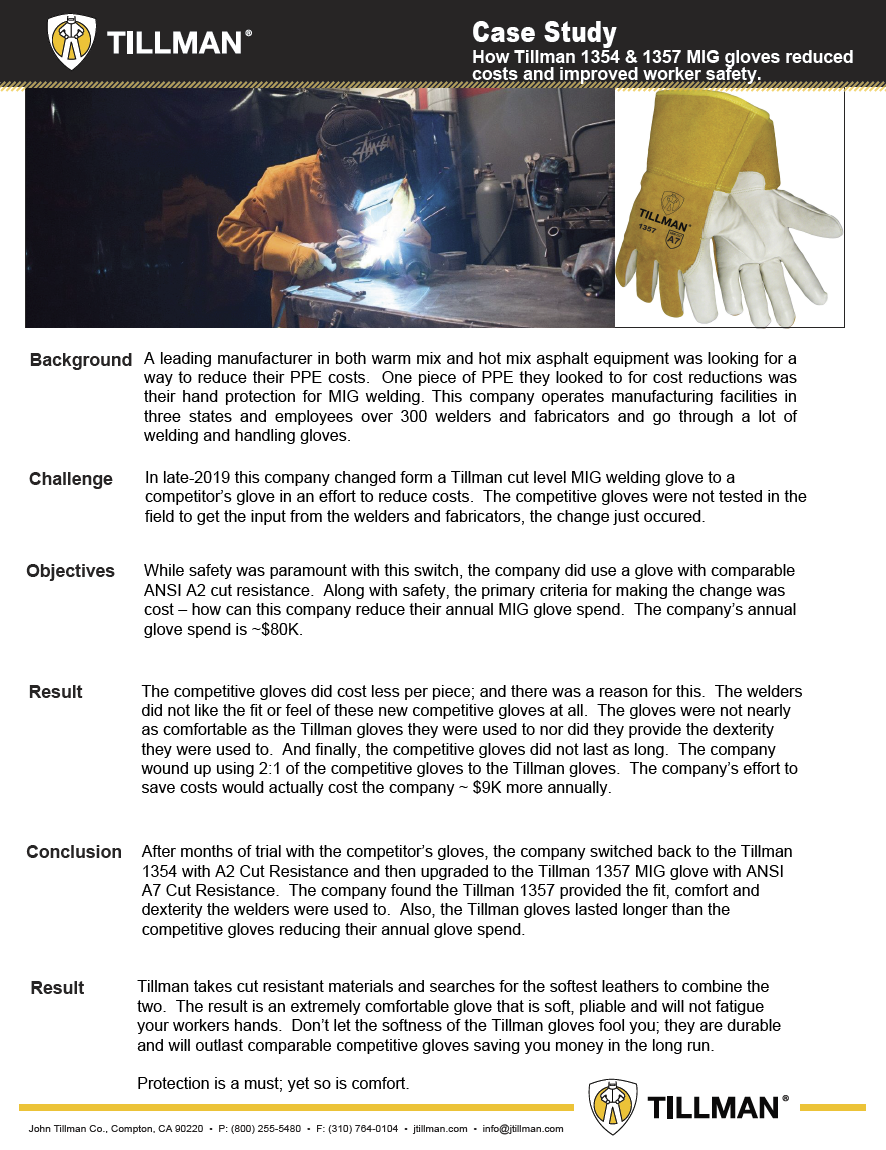

ANSI A7 CUT-RESISTANT MIG WELDING GLOVES WITH COMPREHENSIVE PROTECTION – Tillman ANSI A7 cut-resistant MIG welding gloves feature a complete 360° DuPont™ Kevlar® lining providing industry-leading ANSI A7 cut resistance combined with exceptional dexterity and comfort essential for professional MIG welding applications

PROFESSIONAL-GRADE SAFETY CERTIFICATIONS FOR INDUSTRIAL USE – These ANSI A7 cut-resistant MIG welding gloves are officially rated ANSI Level 4 for abrasion resistance and ANSI Level 5 for puncture resistance, delivering comprehensive protection against the most common welding hazards in a single high-performance glove

PREMIUM TOP GRAIN COWHIDE CONSTRUCTION FOR TACTILE SENSITIVITY – The ANSI A7 cut-resistant MIG welding gloves feature long-lasting top grain cowhide palm and fingers that provide exceptional tactile performance, allowing welders to maintain precise control while benefiting from maximum cut protection

ENGINEERED WING THUMB DESIGN FOR NATURAL WELDING GUN FEEL – A flexible wing thumb design allows greater natural movement for improved grip on the MIG gun or torch, reducing hand fatigue during extended welding sessions

SEAMLESS INDEX FINGER FOR SUPERIOR TRIGGER CONTROL – Crafted with a top grain seamless index finger, these ANSI A7 cut-resistant MIG welding gloves provide welders with enhanced trigger sensitivity and natural feel, delivering precise control for consistent, high-quality MIG welding results

KEVLAR-REINFORCED STITCHING FOR EXCEPTIONAL DURABILITY – Tillman ANSI A7 cut-resistant MIG welding gloves are sewn with genuine DuPont™ Kevlar® thread throughout, providing superior resistance to sparks and spatter while significantly extending glove lifespan in demanding welding environments

PROTECTIVE 4-INCH CUFF FOR EXTENDED COVERAGE – Tillman cut-resistant MIG welding gloves feature a durable 4″ split cowhide cuff that shields your forearm from sparks and spatter while providing essential protection for professionals performing extended MIG welding operations

TRUSTED BY SAFETY-CONSCIOUS PROFESSIONAL WELDERS – Tillman ANSI A7 cut-resistant MIG welding gloves are the preferred choice of certified welders and industrial fabricators who demand the highest safety standards without compromising on the comfort and dexterity required for professional MIG welding

| XS – 1357XS |

XL – 1357XL |

SM – 1357SVM |

XL – 1357XLVM |

| SM – 1357S |

2X – 13572X |

MD – 1357MVM |

2X – 13572XVM |

| MD – 1357M |

3X – 13573X |

LG – 1357LGVM |

3X – 13573XVM |

| LG – 1357L |

|

- ANSI A7 cut resistance certification

- 360° DuPont Kevlar lining

- Top grain cowhide construction

- ANSI level 4 abrasion protection

- ANSI level 5 puncture resistance

- Wing thumb design

- Seamless index finger feature

- 4″ protective cuff length

- DuPont Kevlar thread reinforcement

- Premium welding gun control

- Professional MIG welding approved

- Split cowhide cuff design

Industries

- Automotive Manufacturing and Assembly

- Structural Steel Fabrication and Erection

- Heavy Equipment Production and Repair

- Metal Fabrication Shops and Facilities

- Shipbuilding and Marine Manufacturing

- Manufacturing Plants and Production Lines

- Construction Equipment Manufacturing

- Industrial Machinery Production

- Trailer and Container Fabrication

- Aircraft Component Manufacturing

- Defense Contractor Manufacturing

- Agricultural Equipment Production

- Pipeline Fabrication and Installation

- HVAC Equipment Manufacturing

- Material Handling Equipment Production

- Transportation Equipment Manufacturing

- Industrial Maintenance and Repair

- Metal Stamping and Processing Facilities

- Industrial Storage System Production

- Energy and Power Generation Equipment

Applications

- Professional MIG Welding Operations

- GMAW (Gas Metal Arc Welding)

- Production Line Welding Applications

- High-Volume Fabrication Welding

- Automotive Body Welding and Assembly

- Sheet Metal Fabrication and Assembly

- Structural Steel Component Welding

- Manufacturing Jig and Fixture Welding

- Industrial Repair MIG Applications

- Metal Furniture Manufacturing

- Steel Frame Construction Welding

- Equipment Component Fabrication

- Material Handling Equipment Assembly

- FCAW (Flux-Cored Arc Welding)

- Production Welding Environments

- High-Speed Welding Applications

- Robotic Welding Cell Setup

- Material Handling During Welding

- Industrial Maintenance Welding

- Metal Cabinet and Enclosure Fabrication

- Metal Product Manufacturing

- Tubing and Pipe MIG Welding

- Precision Component Welding

- Industrial Equipment Assembly

- Metal Part Production Welding