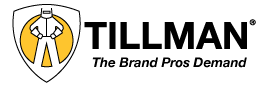

PREMIUM FR COTTON WELDING JACKET FOR SUPERIOR PROTECTION – Tillman’s 6831 FR cotton welding jacket features our economical “Tillman Essentials” 9 oz. flame-resistant cotton fabric that exceeds industry standards, providing welders and industrial workers unmatched protection against sudden flame exposure, sparks, and hazards across welding, oil & gas, and metal fabrication environments. Cotton is ASTM D6413-10 certified

CERTIFIED FLAME RESISTANCE YOU CAN TRUST – This FR cotton welding jacket maintains its flame-resistant properties for up to 50 home washings at 145°F or 25 commercial washings at 165°F

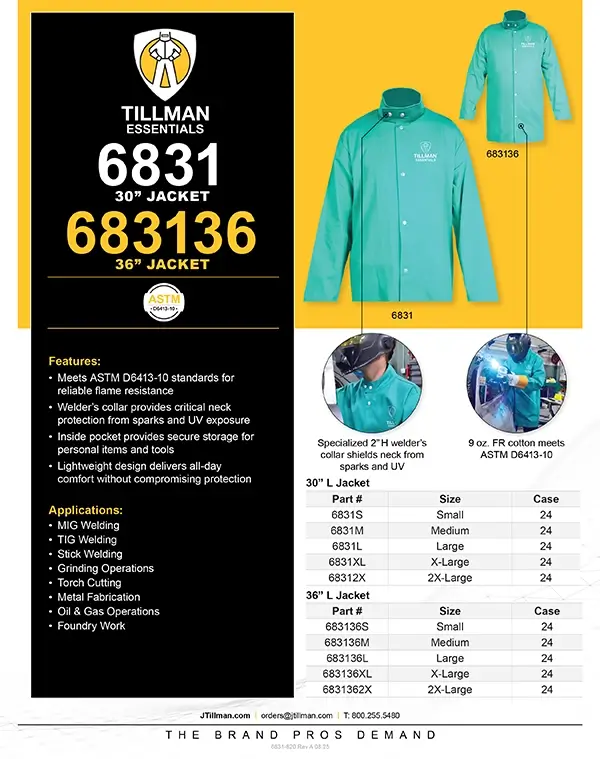

PROTECTIVE COLLAR FOR ENHANCED SAFETY – Designed with a specialized welder’s collar, this FR cotton welding jacket creates a critical protection zone that shields the neck from dangerous sparks, UV exposure, and heat while maintaining comfort during extended MIG and TIG welding sessions

BUILT FOR WELDING AND INDUSTRIAL DURABILITY – This FR cotton welding jacket includes bar tacking at all stress points and corrosion-resistant anodized snaps, ensuring long-lasting performance in demanding welding environments and other high-heat industrial applications

BALANCED COMFORT AND PROTECTION – Experience all-day wearability with this 30″ FR cotton welding jacket that delivers exceptional cooling comfort without compromising on the flame-resistant protection professional welders and industrial workers demand

TRUSTED FLAME RESISTANCE FROM JOHN TILLMAN CO. – Our FR cotton welding jacket represents nearly a century of protective equipment expertise, providing welders with flame-resistant protection they can depend on for MIG welding, TIG welding, stick welding, grinding, torch cutting, and oil & gas operations

| Part # |

Size |

| 6831S |

Small |

| 6831M |

Medium |

| 6831L |

Large |

| 6831XL |

X-Large |

| 68312X |

2X-Large |

| 68313X |

3X-Large |

- 9 oz. FR 100% Cotton Fabric, ASTM D6413-10 certified

- Specialized 2″ H Welder’s Collar

- Convenient Inner Pocket

- 50 Wash cycles, long lasting FR Durability

- 30″ Protective Length

Industries

-

- Welding and Fabrication Shops

- Oil and Gas Production Facilities

- Metal Fabrication Shops

- Petrochemical Refineries

- Power Generation Plants

- Automotive Manufacturing

- Shipbuilding and Marine Repair

- Aerospace Manufacturing

- Steel Mills and Processing Plants

- Mining Operations

- Chemical Processing Facilities

- Agricultural Equipment Manufacturing

- Paper and Pulp Mills

- Construction Sites

- Industrial Maintenance Operations

- Railway Maintenance Facilities

- Manufacturing Plants

- Technical Welding Schools

- Pipeline Construction and Maintenance

- Waste Management Facilities

- Demolition Operations

- Glass Manufacturing

- Wood Processing Plants

- Industrial Cleaning Services

Applications

- MIG Welding Applications

- TIG Welding Operations

- Stick Welding Processes

- Grinding Operations

- Torch Cutting Processes

- Flash Fire Protection

- Electrical Work Near Arc Hazards

- Metal Pouring Operations

- Light to Medium-Duty Fabrication

- Sparking Work Environments

- Equipment Maintenance Tasks

- High-Heat Welding Processes

- Industrial Cleaning Operations

- Assembly Line Production

- Field Welding Operations

- Plant Turnaround Activities

- Machinery Repair Work

- Environments with Fire Risk

- Moderate Heat Exposure Tasks

- Tasks with UV Exposure Risk

- Industrial Maintenance Activities

- Metal Processing Operations

- Surface Preparation Operations

- Arc Flash Risk Environments