Tillman FR Cotton Sleeves – Superior Flame Protection with Elastic Options

FLAME RESISTANT COTTON SLEEVES WITH ELASTIC CUFF OPTIONS – These Tillman Essentials flame resistant cotton sleeves feature 9 oz. FR cotton that meets ASTM D6413-10 standards, available with either internal elastic for comfortable sealing or external elastic cuffs for superior stay-put performance during welding and industrial applications

INDUSTRY-LEADING FLAME RESISTANCE MAINTAINS INTEGRITY – All Tillman flame resistant cotton sleeves maintain their protective properties for up to 50 home washings at 145°F or 25 commercial washings at 165°F, ensuring long-term reliability and consistent flame protection shift after shift

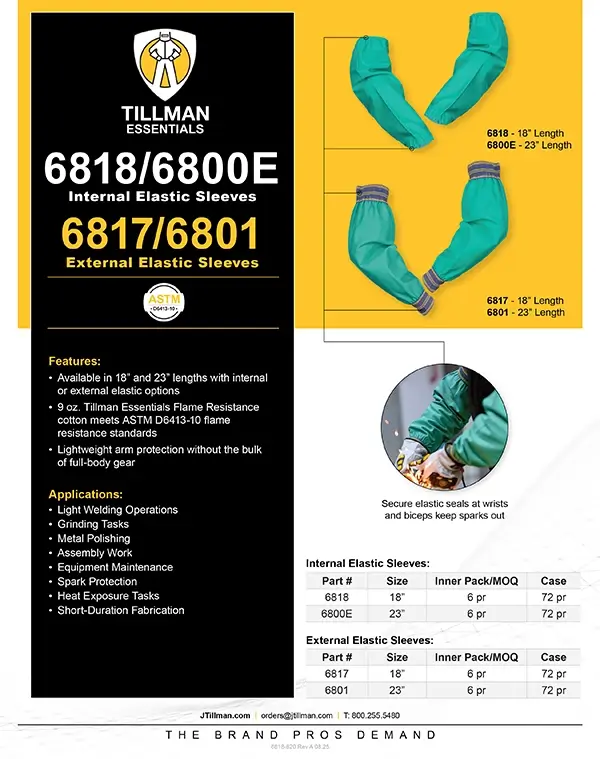

CHOOSE YOUR ELASTIC CONFIGURATION FOR OPTIMAL PERFORMANCE – Internal elastic models (6800E/6818) create dependable seals keeping sparks and debris out while maintaining comfortable mobility, while external elastic models (6801/6817) feature extra-wide 2¼” cuffs that deliver unmatched stay-put performance during overhead work and dynamic movements

TWO LENGTH OPTIONS FOR PERFECT COVERAGE – Available in both 18″ and 23″ lengths across all elastic configurations, these flame resistant cotton sleeves provide customizable coverage based on your specific welding position and application requirements

COOL AND BREATHABLE COMFORT FOR ALL-DAY WEAR – The 9 oz. Tillman Essentials FR cotton construction delivers the perfect balance of protection and breathability, moving with you while keeping you cool during hot, intensive welding and fabrication work

TRUSTED FLAME PROTECTION FROM AMERICA’S WELDING SAFETY LEADER – Tillman flame resistant cotton sleeves deliver reliable protection and comfort at an economical price point when safety cannot be compromised

Internal Elastic Sleeves

| Part # |

Length |

| 6818 |

18″ |

| 6800E |

23″ |

External Elastic Sleeves

| Part # |

Length |

| 6817 |

18″ |

| 6801 |

23″ |

- Premium 9oz FR cotton construction

- ASTM D6413-10 certified protection

- Internal or external elastic options

- 18″ and 23″ length choices

- Washable flame resistant material

- 50+ wash protection durability

- Cool breathable comfort

- Trusted Tillman quality

- Superior stay-put performance

- Designed for light-duty welding only

- Structural Steel Fabrication

- Pipeline Welding Operations

- Automotive Manufacturing

- Aerospace and Aviation Assembly

- Shipbuilding and Marine Construction

- Metal Fabrication Workshops

- Industrial Maintenance Facilities

- Construction Projects

- Oil and Gas Refineries

- Power Generation Plants

- Chemical Processing Facilities

- Technical and Vocational Schools

- Railway Maintenance Operations

- Heavy Equipment Manufacturing

- Defense Manufacturing

- Bridge Construction and Repair

- Steel Mill Operations

- HVAC Installation Projects

- Tank and Vessel Manufacturing

- Mining Equipment Maintenance

- Agricultural Equipment Fabrication

- Manufacturing Training Programs

- Commercial Construction Sites

- Industrial Production Environments

- Energy Sector Maintenance

- Overhead Welding Operations

- Protection Against Sudden Flames

- Dynamic Movement Applications

- Medium to Heavy-Duty Welding

- Working in Confined Spaces

- Vertical Position Welding

- Protection During Metal Cutting

- Electrical Work Environments

- Training and Educational Settings

- Situations Requiring Stable Arm Protection

- Arc Flash Protection Applications

- Heavy Fabrication Projects

- Field Welding Operations

- Maintenance Repair Operations

- Working with High-Temperature Materials

- Assembly Line Welding Tasks

- Spatter Protection Applications

- Secondary Fire Protection

- Metal Grinding Operations

- Torch Cutting Applications

- Brazing and Soldering Tasks

- High Heat Work Environments

- Multi-Process Welding Projects

- Applications Requiring Superior Stability

- Medium to Heavy Industrial Applications