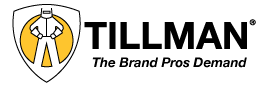

Product Overview

Tillman® Essentials™ Flame Resistant 100% Cotton Bib Apron

- Premium flame resistant bib apron providing superior protection for MIG/TIG welding, oil & gas, and metal fabrication work

- Tillman Essentials 9oz FR cotton construction meets rigorous ASTM D6413-10 flame resistance standards for industrial safety

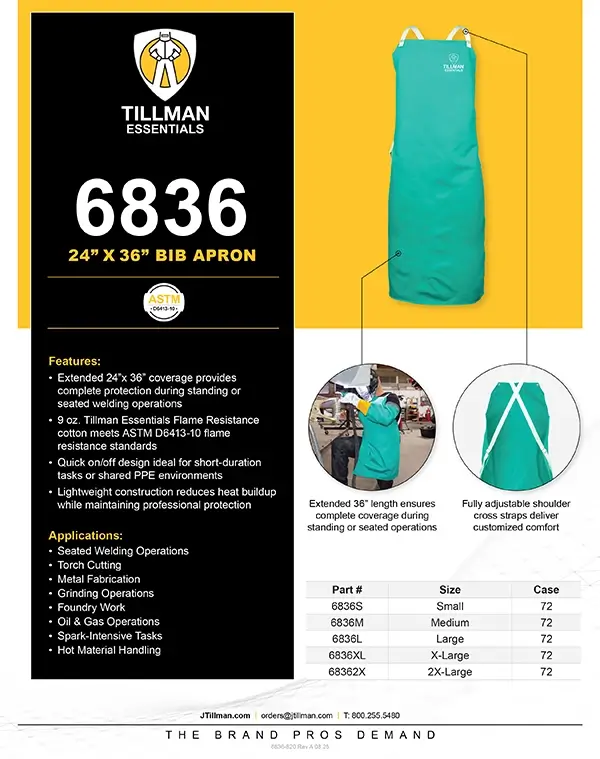

- Extended 36″ length ensures complete coverage during seated welding operations, torch cutting, and other spark-intensive tasks

- Fully adjustable shoulder cross straps deliver customized comfort and secure fit for all-day wear

- Maintains flame resistance for up to 50 home washings, delivering outstanding value and durability for safety programs

- Trusted by professionals in multiple industries for essential protection against sudden flame exposure, flying sparks, and hot materials